Why Used Dock Ramps?

At Medlin Ramps, we understand that efficiency and cost-effectiveness are two of the pillars upon which successful businesses are built. Used dock ramps represent an incredible opportunity for businesses to enhance their logistic and material handling capabilities without the hefty price tag of new equipment. With over 30 years in the industry, our expertise has shown us that a well-maintained used ramp can perform just as reliably as a new one, providing an excellent return on investment.

Benefits of Choosing Used Ramps

Cost-Effectiveness

In the quest to balance the books, sourcing used dock ramps can significantly reduce upfront costs. Our inventory of used ramps offers the same high quality as new models but at a fraction of the cost. This opens up budget space for other critical investments within your operation.

Environmental Impact

Choosing used equipment isn’t just good for your wallet; it’s a step towards sustainability. By re-utilizing high-grade industrial equipment, we help reduce the demand for new materials and the energy consumption associated with manufacturing new ramps. It’s an easy way to lessen your company’s carbon footprint.

Immediate Availability

One of the inherent advantages of opting for used dock ramps is bypassing the manufacturing lead time. Our extensive inventory ensures that you can find a ramp that fits your needs and have it delivered to your site without the wait, keeping your projects on schedule.

Our Expertise

At Medlin Ramps, our commitment to excellence is reflected not just in the products we sell but in the comprehensive service we provide. Over three decades, we’ve refined our approach to ensure the highest standards of quality and customer satisfaction. Whether you are buying, renting, or seeking a custom solution, our team is dedicated to finding the perfect fit for your operational requirements.

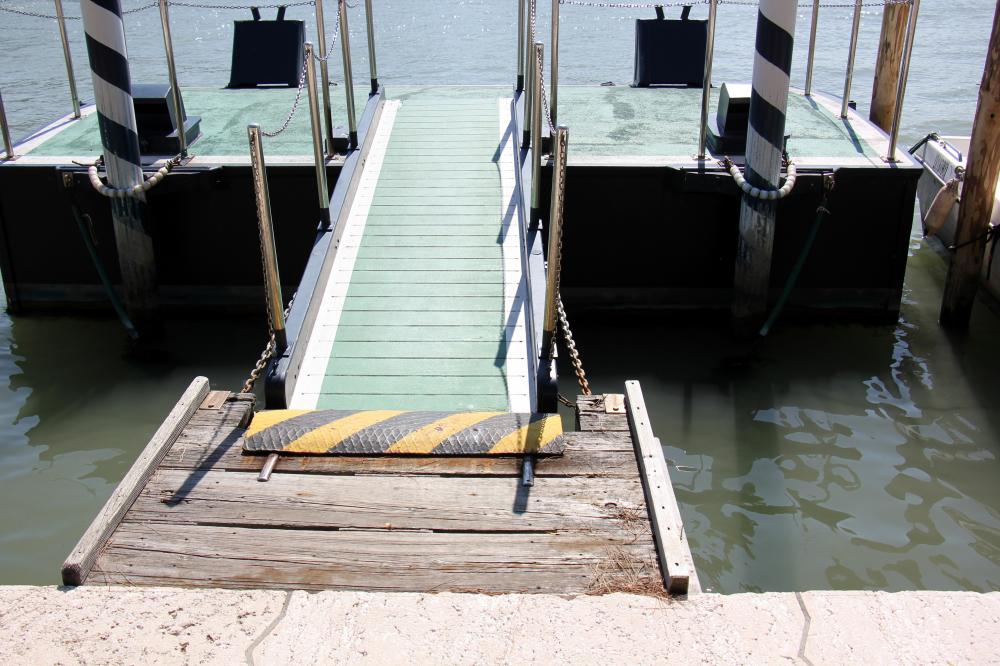

Features of Used Dock Ramps

Our selection of used dock ramps is designed to meet the diverse needs of the modern warehouse and loading dock. Each ramp is carefully inspected and serviced to meet our rigorous standards, ensuring reliability and safety. With features like heavy-duty carbon steel construction, hydraulic adjustments, and mobile or stationary options, our ramps provide the versatility and durability businesses need to thrive in today’s fast-paced market.

Choosing the Right Ramp

Understanding your specific needs is crucial when selecting a dock ramp. From weight capacity and ramp length to mobility and storage, each aspect should be considered to ensure optimal efficiency and safety. Our team leverages years of industry experience to guide you through the selection process, ensuring that the ramp you choose aligns perfectly with your operational goals.

Success Stories

Throughout our history, we’ve been privileged to work with a wide array of businesses, from small start-ups to large corporations. These partnerships have not only allowed us to refine our offerings but have also provided us with invaluable insights into the challenges and solutions related to material handling. Our success stories include businesses that have dramatically improved their productivity and safety by integrating our used dock ramps into their operations.

Environmental Sustainability

In every aspect of our operations, from manufacturing to delivery, we strive to minimize our environmental impact. By offering used dock ramps, we’re not just presenting a cost-effective solution; we’re advocating for a more sustainable approach to industrial equipment usage. This commitment to environmental stewardship is an integral part of our corporate ethos and one that we’re proud to share with our customers.

Looking Ahead

As we continue to grow and evolve, our dedication to providing high-quality, sustainable solutions remains unwavering. The landscape of material handling is constantly changing, and with it, our strategies and offerings. What will never change is our commitment to excellence, sustainability, and above all, serving the needs of our customers. By choosing Medin Yard Ramps for your used dock ramps needs, you’re not just making a purchase; you’re investing in a partnership dedicated to your success.

Why Choose Used Dock Ramps?

We’ve seen over decades that efficiency and cost savings don’t have to come at the expense of quality. Opting for a used dock ramp is a perfect illustration of this principle. A well-maintained used ramp offers the same performance as a brand-new one. This is because the essential integrity and functionality of the ramp are preserved through meticulous servicing and quality checks. Think of it as buying a certified pre-owned vehicle–it’s not just about economic savings; it’s about trusting that you’re getting value without compromise.

What Are Common Misconceptions About Used Dock Ramps?

A common misconception is that used dock ramps are less safe or reliable than new ones. However, the truth is quite the opposite. Each ramp undergoes thorough inspections and servicing to meet rigorous standards before it’s deemed fit for sale. It’s like how a carefully restored classic car can meet or even exceed modern safety standards–through careful attention to detail and expert craftsmanship.

What Are the Environmental Benefits of Choosing Used Dock Ramps?

Choosing used dock ramps significantly contributes to environmental sustainability. By reusing and repurposing industrial equipment, we not only conserve resources but also reduce the demand for new material production, which in turn, decreases the overall carbon footprint associated with manufacturing. It’s akin to recycling at a larger scale, where every reused ramp represents a step towards more sustainable industry practices.

How to Select the Right Used Dock Ramp?

Selection should be guided by your specific operational needs–consider the weight capacity, length, mobility, and storage of the ramp. It’s similar to choosing a vehicle; you wouldn’t pick a compact car to tow a heavy trailer. Our team leverages extensive industry experience to help guide you to the perfect ramp for your operations, ensuring that it aligns not just with your immediate requirements but also your long-term operational goals.

Can You Share Stories of Success with Used Dock Ramps?

Over the years, we’ve seen numerous businesses transform their productivity and safety by integrating our used dock ramps into their operations. One example includes a start-up warehousing company that, with a limited budget, was able to double its loading capacity and efficiency by opting for a used ramp. This not only supported its growth but also established a strong foundation for its future. It’s stories like these that fuel our commitment to providing high-quality, sustainable solutions to our customers.

How Do Used Dock Ramps Support Business Growth?

By offering a cost-effective, immediately available, and reliable loading solution, used dock ramps significantly contribute to the scalability of operations. They enable businesses to increase their handling capacity without incurring the high costs associated with new equipment, allowing them to allocate resources more effectively across their operations. It’s a principle of smart investment–putting your resources where they yield the highest return.

Why Is Maintenance Important for Used Dock Ramps?

Maintenance is key to ensuring the longevity, safety, and reliability of used dock ramps. Regular servicing helps to prevent potential issues and ensures the ramp performs efficiently over its lifespan. Think of it as maintaining peak performance in a high-performance engine–it requires regular checks and fine-tuning to keep it running smoothly and extend its service life.

How to Get Started with a Used Dock Ramp?

Getting started is simple. Reach out to our team with your specific requirements, and we’ll guide you through the selection process, ensuring that you find a ramp that fits your operational needs perfectly. From assessing your site to understanding your material handling challenges, we’re here to provide a seamless and supportive experience from start to finish. It’s like embarking on a new journey–we’re here to navigate and ensure a smooth ride.

Resources

- U.S. Environmental Protection Agency (EPA) – The EPA provides valuable information on environmental sustainability and the importance of reusing equipment to reduce carbon footprint. Visit the EPA website

- U.S. Department of Energy – The DOE offers insights into energy consumption associated with manufacturing new equipment and promotes the use of reused industrial materials. Visit the Department of Energy website

- Environmental Protection Agency (EPA) – The EPA’s Sustainable Materials Management program focuses on reducing environmental impact through reusing industrial equipment like dock ramps. Visit the EPA’s SMM page

Santa Fe Springs CA 90670